In the ever-evolving world of industrial processing, where extreme temperatures, corrosive chemicals, and aggressive operating environments are the norm, the materials used to construct process equipment must meet exceptional standards. Over time, exotic metals such as Titanium, Hastelloy, Zirconium, Tantalum, and Inconel have emerged as game-changers.

Among these, Titanium and Hastelloy stand out as the workhorses of modern process equipment—trusted across industries like chemical processing, pharmaceuticals, petrochemicals, pulp and paper, and fertilizer production.

The Corrosion Challenge in Process Industries

One of the biggest challenges in industrial applications is corrosion. It not only deteriorates equipment but also leads to:

- Contamination of the end product

- Unexpected downtime

- Increased maintenance costs

- Safety hazards

Standard stainless steel or carbon steel equipment often fails when exposed to acids, chlorides, seawater, and oxidizing agents. That’s where exotic metals step in, offering unmatched resistance to corrosive environments.

Titanium: The Lightweight, Corrosion-Proof Metal

Titanium is a silvery-grey transition metal known for its incredible strength-to-weight ratio and exceptional corrosion resistance.

Key Properties of Titanium:

- Corrosion resistance: Titanium forms a passive oxide layer (TiO₂) which protects it from corrosive attack, particularly in chloride-rich and oxidizing environments.

- High strength, low weight: It is 45% lighter than steel, making it ideal for large equipment that needs to be moved or suspended.

- Excellent biocompatibility: Makes it suitable for pharmaceutical and high-purity applications.

- Temperature resilience: Performs well in high temperatures up to 600°C (depending on grade).

Common Applications of Titanium in Process Equipment

- Titanium reactors and vessels for handling chlorine-based chemicals

- Heat exchangers used in seawater cooling systems

- Evaporators in fertilizer and caustic soda industries

- Condensers in power plants and refineries

Grades of Titanium Used

- Grade 2: Commercially pure, used widely in chemical processing

- Grade 5 (Ti-6Al-4V): Titanium alloyed with aluminum and vanadium for added strength

- Grade 12: Titanium alloyed with Mo and Ni for improved weldability and corrosion resistance

Hastelloy: The Alloy Built for Aggression

Hastelloy is a nickel-molybdenum-chromium superalloy designed to handle the harshest chemical environments, especially where other metals fail.

🔹 Key Properties of Hastelloy

- Outstanding resistance to oxidizing and reducing agents

- Excellent performance in wet chlorine gas, hydrochloric acid, and sulfuric acid

- Highly weldable and retains its corrosion resistance even after welding

- Withstands pitting, crevice corrosion, and stress corrosion cracking (SCC)

🔹 Common Applications of Hastelloy in Process Equipment

- Reboilers, reactors, and vessels in chemical plants

- Heat exchangers in acidic environments

- Spray nozzles and agitators exposed to mixed acids

- Storage tanks for hazardous or aggressive chemical media

🔹 Popular Hastelloy Grades

- Hastelloy C-276: Known for broad resistance to severe environments including strong oxidizers and reducers

- Hastelloy C-22: Offers improved resistance to crevice corrosion and SCC in oxidizing media

- Hastelloy B-2: Resistant to hydrochloric acid and other strongly reducing media

Titanium vs. Hastelloy: A Technical Comparison

Property | Titanium Grade 2 | Hastelloy C-276 |

Density | 4.51 g/cm³ | 8.89 g/cm³ |

Corrosion Resistance | Excellent (chlorides, seawater) | Outstanding (acids, oxidizers) |

Max Operating Temp | ~600°C | ~1040°C |

Strength | Medium | High |

Weldability | Excellent | Excellent |

Cost | Moderate (vs. exotic alloys) | High |

Titanium is often preferred when weight savings and resistance to chlorides are crucial. Hastelloy is selected where high strength and resistance to acids (especially mixed or strong oxidizers) are required.

Why Industries Are Shifting to Exotic Metal Fabrication

- Lower Lifetime Cost

Despite higher upfront material costs, exotic metals significantly reduce maintenance, extend equipment life, and lower total cost of ownership.

- Improved Safety & Compliance

In industries like pharmaceuticals or chemicals, equipment failure can lead to contamination or safety incidents. Exotic metals help meet strict regulatory standards and offer peace of mind.

- Custom Fabrication Flexibility

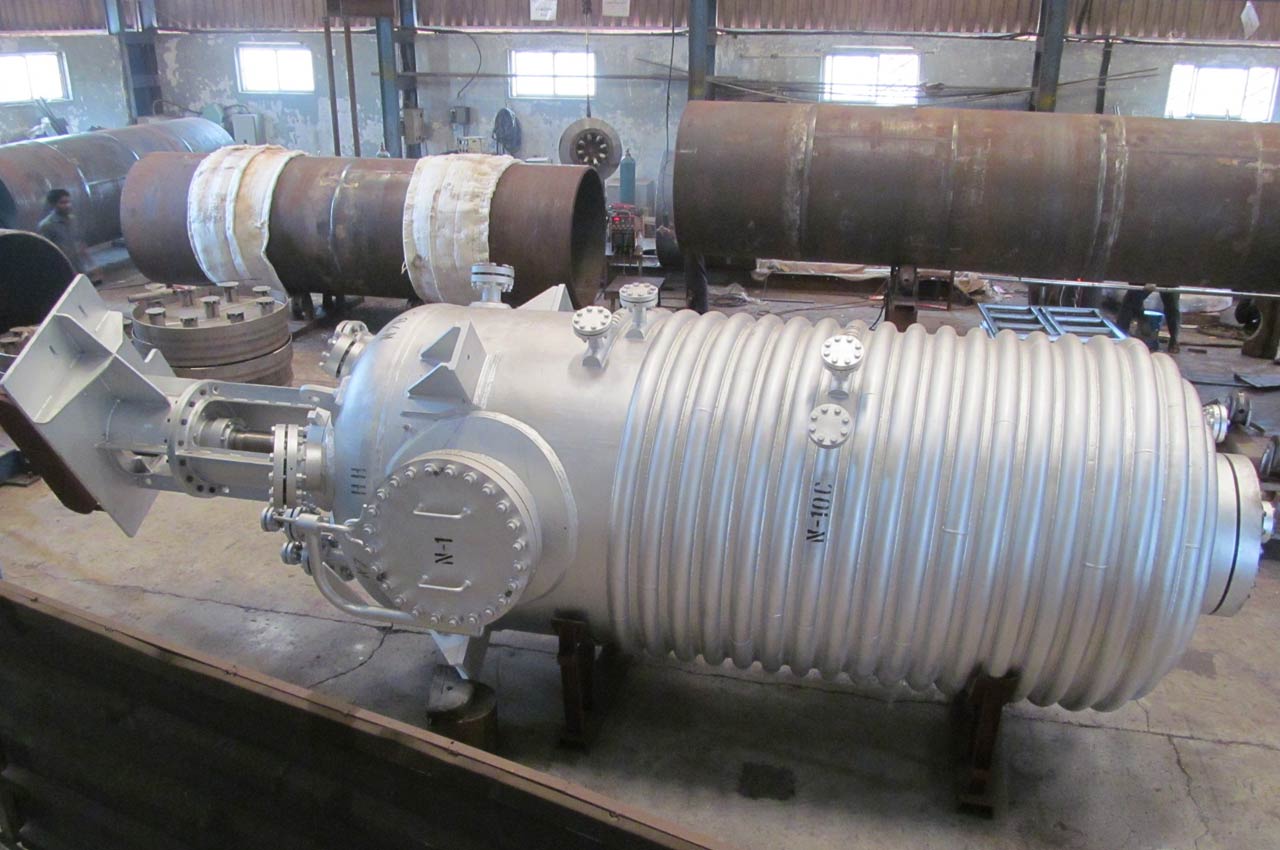

At EXOTIC FABTECH, we design and fabricate:

- Reactors & Agitators

- Cladded Vessels

- Heat Exchangers

- Distillation Columns

- Lined Thermo Pockets

… and many more using Titanium, Hastelloy, and other exotic metals.

We use advanced fabrication techniques, including TIG/MIG welding, orbital welding, cladding, and custom machining to meet precise tolerances.

Case Example: Titanium Cladded Reactor in a Chlor-Alkali Plant

A leading chlor-alkali plant was facing frequent corrosion failures in its stainless-steel reactor. Our team designed a Titanium-cladded reactor, combining the structural integrity of carbon steel with the corrosion protection of Titanium.

Results:

- Equipment life extended by over 10 years

- Zero contamination

- Significant reduction in maintenance costs

In today’s aggressive industrial environments, Titanium and Hastelloy have become the materials of choice for high-performance, long-lasting process equipment. Whether you’re facing hydrochloric acid attack, chloride stress corrosion, or severe oxidizers, these metals offer the best defense against equipment failure and operational downtime.

At EXOTIC FABTECH, we bring decades of expertise in designing and fabricating custom corrosion-resistant equipment using these exotic metals—ensuring performance, safety, and reliability for your operations.

Ready to Upgrade to Exotic Metal Equipment?

Our technical team is here to help you choose the right material for your application.

Email us at: exotic@exoticfabtech.com

Call us: +91-22-35219442