In today’s rapidly evolving industrial landscape, process equipment must not only meet current performance requirements—but also be resilient, sustainable, and adaptable for future demands. With increasing focus on energy efficiency, environmental compliance, and extreme process conditions, the metal fabrication industry is undergoing a transformation.

From exotic alloys to Industry 4.0-driven manufacturing, let’s explore the key trends shaping the future of metal fabrication in chemical, petrochemical, fertilizer, and pharmaceutical industries—and how you can ensure your equipment is future-ready.

Why Modern Process Equipment Needs to Evolve

The traditional approach of selecting standard-grade materials for generic use is no longer sufficient. Today’s industrial plants demand:

- Higher resistance to corrosion and abrasion

- Enhanced thermal and mechanical performance

- Compatibility with aggressive chemicals

- Reduced downtime and increased life cycles

- Compliance with sustainability norms and energy efficiency

Meeting these expectations requires not just smart engineering—but also advanced fabrication practices and innovative use of materials.

Trend 1: Rise of Exotic Metals & High-Performance Alloys

Materials like Titanium, Tantalum, Hastelloy, Inconel, Zirconium, and Monel are becoming increasingly critical in equipment fabrication. These exotic metals offer superior corrosion resistance, longer service life, and consistent performance under extreme conditions.

Benefits driving adoption:

- Titanium: Ideal for chloride-rich environments and seawater applications.

- Hastelloy C-276/C-22: Excellent for mixed acid and oxidizing environments.

- Inconel 625: Withstands high temperatures and high-pressure gas streams.

- Zirconium: Unmatched in handling nitric and hydrochloric acids.

- Tantalum: Near immunity to acid attack—even at high concentrations.

EXOTIC FABTECH is at the forefront of leveraging these metals to engineer cost-effective, long-lasting equipment such as reactors, heat exchangers, storage vessels, and pressure tanks.

Trend 2: Integrated Fabrication Technologies

Advancements in metal fabrication now combine precision machining, advanced welding, and surface finishing to enhance equipment performance.

Key developments include:

- CNC-controlled cutting and bending: Ensures precision and repeatability.

- Orbital and TIG welding of exotic metals: Minimizes weld defects and enhances integrity under pressure.

- Cladding and lining technologies: Combine exotic metals with base materials to reduce cost while maintaining corrosion resistance.

- Automated inspection and NDT (Non-Destructive Testing): For 100% quality assurance.

These practices not only improve equipment strength and efficiency but also shorten lead times and reduce manufacturing costs.

Trend 3: Regulatory Compliance & Sustainability

Industries are under growing pressure to meet global environmental and safety standards. This drives the need for materials and equipment that:

- Reduce contaminant leaching or emissions

- Enable cleaner processing technologies

- Withstand aggressive scrubbing, recovery, or regeneration systems

- Comply with ASME, TEMA, GMP, and ISO guidelines

Equipment made with high-purity exotic metals and clean weld environments is essential for pharmaceutical, food, and biotech sectors where product purity and cross-contamination are concerns.

Trend 4: Tailored, Project-Specific Engineering

Rather than relying on generic designs, companies now demand custom-engineered solutions that are:

- Optimized for their specific chemical processes

- Designed for space-saving installations

- Equipped to handle future process upgrades

- Integrated with advanced safety and monitoring features

At EXOTIC FABTECH, we take pride in offering bespoke equipment design and fabrication using the world’s most corrosion-resistant and high-performance metals.

How to Future-Proof Your Process Equipment

- Invest in the right material for your process

Don’t cut costs with inferior metal grades. Select exotic alloys that match your media, temperature, and pressure conditions.

- Focus on fabrication quality

Ensure your vendor has experience in working with exotic metals, proper certifications, and a proven QA/QC track record.

- Choose modular, upgrade-ready designs

Allow for process expansion, easy maintenance, and future automation integration.

- Prioritize documentation and traceability

From MTCs (Mill Test Certificates) to weld maps, documentation ensures compliance and peace of mind.

- Work with a partner, not just a supplier

A reliable equipment fabricator offers design guidance, material selection support, lifecycle assistance, and post-installation service.

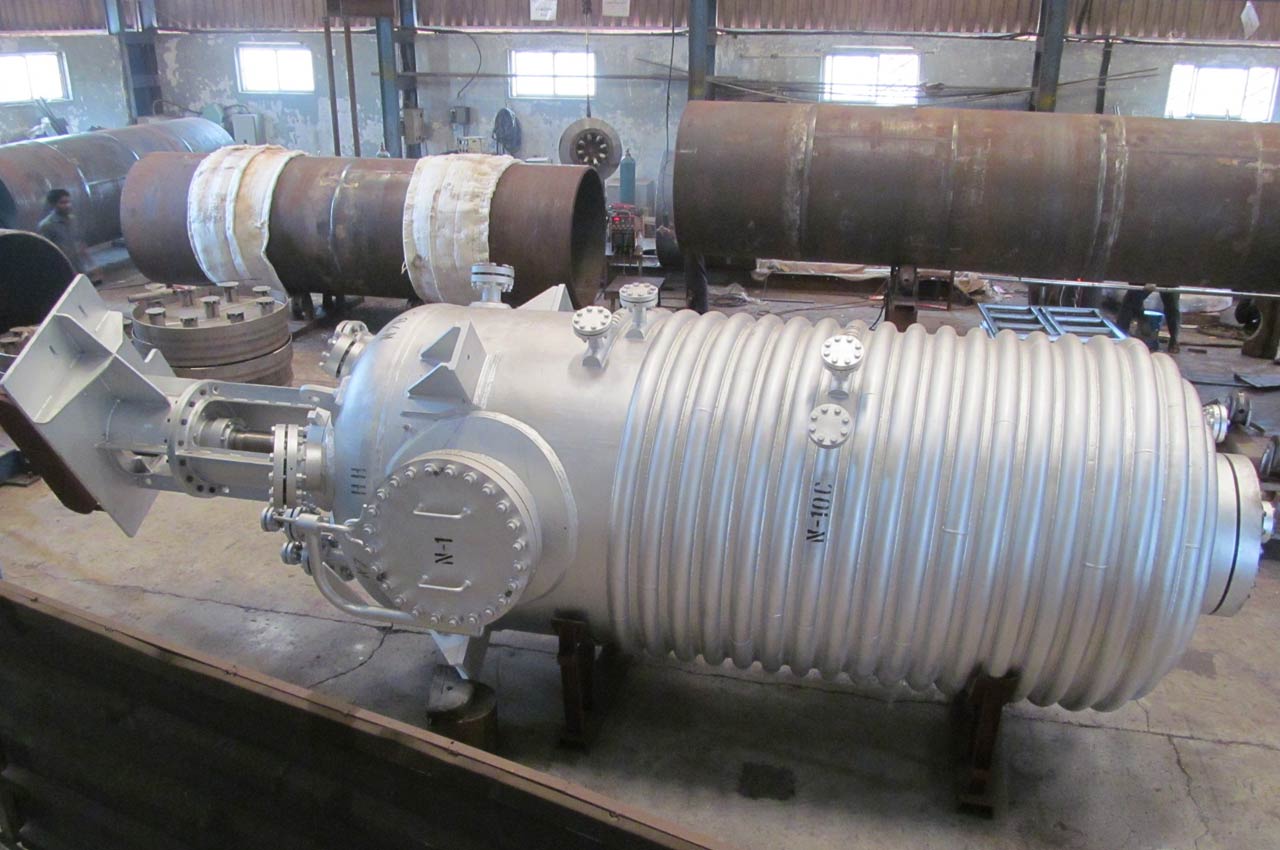

Case Study: Future-Ready Titanium Cladded Reactor for a Fertilizer Plant

A leading fertilizer manufacturer was struggling with repeated corrosion failures in their ammonium chloride process line. Their carbon steel reactors, even with SS cladding, were failing in under two years.

EXOTIC FABTECH Solution:

- Designed a Titanium cladded reactor vessel

- Optimized wall thickness and heat zones using advanced simulation

- Fabricated with orbital welding and 100% radiography

- Delivered documentation pack: MTCs, WPS, PQR, NDT, and final inspection reports

Result:

- Reactor has completed 4.5 years in continuous operation

- No internal corrosion, zero downtime

- Complies with global environmental norms for emissions

The future of metal fabrication for process industries lies in precision, customization, and the use of high-performance materials. As environmental regulations tighten and process conditions grow harsher, equipment must be engineered not only to survive—but to thrive under pressure.

Whether you’re upgrading existing systems or building a new facility, now is the time to ask: Is your equipment future-ready?

📞 Talk to the Experts at EXOTIC FABTECH

From Titanium reactors to Hastelloy heat exchangers, we design and fabricate process equipment that is built for tomorrow’s challenges.

Email: exotic@exoticfabtech.com

Call us: +91-22-35219442