In the high-stakes world of petrochemical manufacturing, performance is everything. From ethylene production to refining hydrocarbons, these plants operate under extreme conditions—high temperatures, corrosive chemicals, and demanding thermal loads. At the heart of these critical operations lies one of the most essential pieces of process equipment: the heat exchanger.

While standard designs may serve basic thermal duties, custom-engineered heat exchangers made from exotic metals like Titanium, Hastelloy, Inconel, and Monel play a pivotal role in ensuring uninterrupted, efficient, and safe plant operations. In this article, we go inside the petrochemical process to uncover how these specialized units deliver superior performance and why choosing the right materials and design makes all the difference.

The Role of Heat Exchangers in Petrochemical Plants

Heat exchangers are responsible for transferring heat from one fluid to another—either to heat up or cool down process streams. In a typical petrochemical facility, heat exchangers are involved in:

- Pre-heating raw materials before cracking or distillation

- Cooling down cracked gases or product streams

- Condensing vapor into liquid form

- Heat recovery systems to improve energy efficiency

A failure in any of these systems could mean process shutdown, loss of product, or even a safety hazard.

Why Customisation is Critical

No two petrochemical plants are the same. Different process parameters, space constraints, media types, and operating pressures demand tailored solutions, not off-the-shelf units.

Key reasons for customizing heat exchangers:

- Corrosive fluid handling: Many fluids—especially acids, hydrogen sulfide (H₂S), and chlorides—can corrode standard materials like carbon steel or even SS 316L.

- Extreme temperatures: Cracking units operate above 400°C, while cryogenic separation may go below -100°C.

- Space limitations: Plants often require compact designs that fit into tight layouts without sacrificing performance.

- Process-specific performance: Whether it’s film condensation or turbulent flow, thermal performance must match the exact process requirement.

Custom heat exchangers, designed with the right flow configuration, surface area, and material, ensure optimal heat transfer and longer life—even under harsh duty cycles.

Materials Matter: Why Exotic Alloys Rule

One of the key differentiators in heat exchanger performance—especially in petrochemical environments—is the choice of construction material.

1. Titanium

- Applications: Chloride-rich streams, seawater cooling, wet chlorine service

- Benefits: Lightweight, high strength, excellent corrosion resistance

- Use Case: Titanium tube bundles for seawater condensers

2. Hastelloy (C-276 / C-22)

- Applications: Sulfuric acid, HCl vapors, mixed acid media

- Benefits: Exceptional resistance to both oxidizing and reducing agents

- Use Case: Reboilers or condensers in acid gas environments

3. Inconel (600 / 625)

- Applications: High-temperature applications, especially hydrogenation units

- Benefits: Excellent mechanical strength, oxidation resistance

- Use Case: Heat exchangers in reformers and cracker units

4. Monel

- Applications: Hydrofluoric acid environments, alkylation units

- Benefits: Resistance to hydrofluoric acid and caustic solutions

- Use Case: Condensers in HF acid service

By integrating these high-performance alloys into custom-designed heat exchangers, manufacturers can significantly reduce failure rates, extend maintenance intervals, and improve plant uptime.

Types of Heat Exchangers Used in Petrochemical Plants

While there are many types of heat exchangers, the following are most commonly used in petrochemical plants:

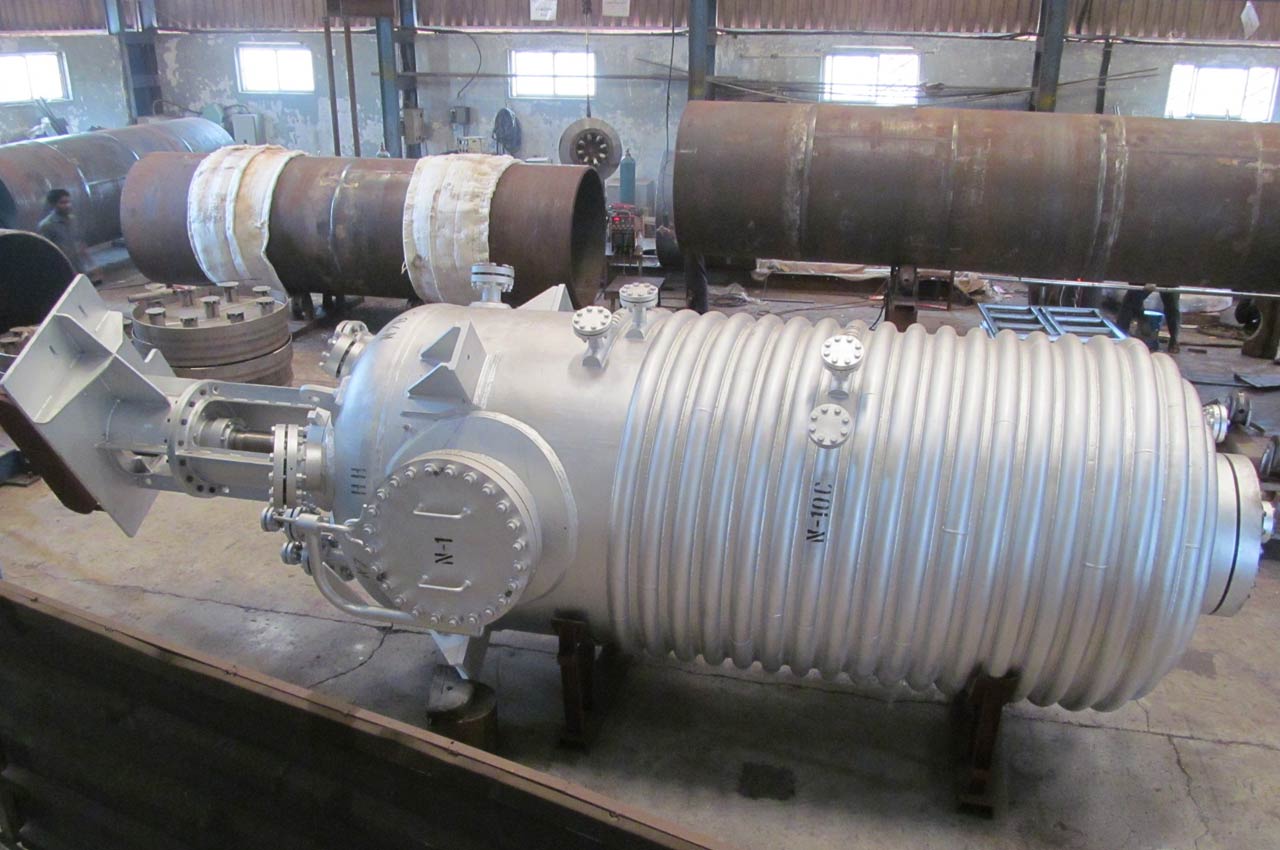

1. Shell & Tube Heat Exchangers

- Most widely used due to versatility and scalability

- Ideal for high-pressure and high-temperature processes

- Can be custom-designed with multiple passes, baffles, and exotic materials

2. Double Pipe Heat Exchangers

- Simple, easy to clean

- Ideal for smaller systems or corrosive fluids

- Often used where frequent maintenance is required

3. Air-Cooled Heat Exchangers

- Use ambient air instead of cooling water

- Reduce water usage and cooling tower dependency

- Often used in refineries and remote installations

4. Plate Heat Exchangers (PHE)

- Compact with high surface area per volume

- Best for clean fluids and temperature-sensitive applications

- Not always suitable for highly viscous or dirty fluids unless custom-adapted

Real-World Example: Custom Hastelloy Heat Exchanger in Acid Recovery Unit

One of our clients—a major petrochemical manufacturer—was facing rapid corrosion in its acid recovery unit due to mixed acid vapors at high temperatures. The standard SS 316L heat exchanger required tube replacement every 9 months, causing regular shutdowns and production losses.

Solution by EXOTIC FABTECH:

- Designed a custom shell & tube heat exchanger

- Used Hastelloy C-276 tubes and tube sheets

- Optimized baffle spacing for enhanced flow and reduced vibration

Result:

- Unit has been in operation for over 4 years without failure

- Maintenance costs reduced by 70%

- ROI achieved within 14 months

Design Considerations in Custom Heat Exchanger Fabrication

When designing a custom unit, we focus on the following:

- Fluid compatibility – Matching material to chemical composition

- Thermal duty – Accurate calculation of surface area and flow paths

- Pressure rating – Designing for internal pressure and thermal expansion

- Fouling resistance – Smooth internal surfaces and self-cleaning design

- Ease of maintenance – Modular or accessible layout for quick servicing

- Welding integrity – Specialized TIG/MIG welding of exotic metals

- Certifications – ASME, TEMA, and customer-specific standards

At EXOTIC FABTECH, we bring these principles into every heat exchanger we design—ensuring your process runs smoother, longer, and safer.

Why Partner with EXOTIC FABTECH?

- Material expertise: We specialize in Titanium, Tantalum, Hastelloy, Inconel, Zirconium, and other exotic alloys.

- Custom engineering: Each heat exchanger is uniquely designed to meet your exact process needs.

- Quality assurance: Every unit is tested for pressure, weld integrity, and thermal performance.

- Fast delivery: In-house fabrication capabilities for reduced lead time.

- End-to-end support: From design consultation to commissioning and after-sales service.

In a high-performance environment like a petrochemical plant, equipment that simply “does the job” isn’t enough. It must withstand harsh chemicals, resist failure, and maximize energy recovery. That’s exactly what custom heat exchangers made from exotic metals are built for.

When designed right, these heat exchangers become the backbone of thermal efficiency and process reliability. And at EXOTIC FABTECH, that’s exactly what we deliver—performance built to last.

Ready to Upgrade Your Heat Exchangers?

Let us design a custom solution for your process plant.

Email: exotic@exoticfabtech.com

Call us: +91-22-35219442